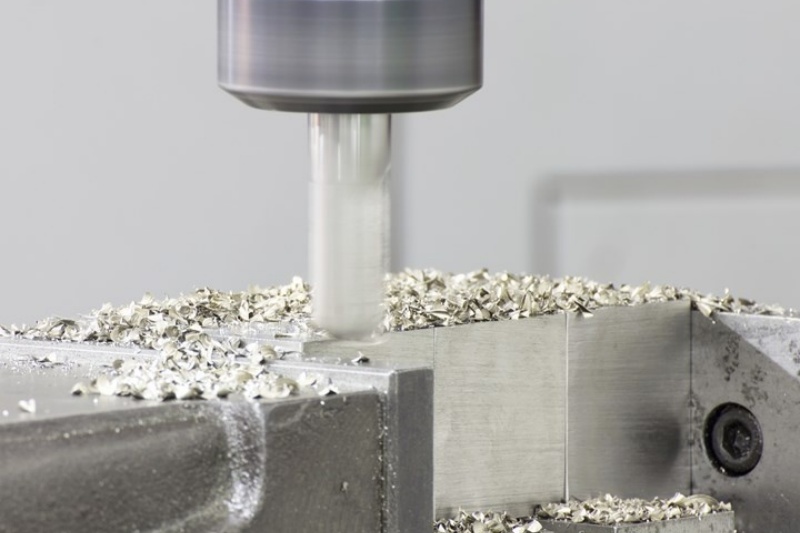

In modern manufacturing, CNC (computer numerical control) machining technology has become the core technology for improving production efficiency and machining accuracy. According to different machining requirements, heavy cutting and high-speed machining are two common CNC machining modes. They each have different advantages and disadvantages and are suitable for different application scenarios. This article will compare and analyze these two machining modes to help companies make the best decision when choosing a machining method.

1. Heavy Cutting

Advantages:

Suitable for large size and high hardness materials: The heavy cutting mode is particularly suitable for machining large size and high hardness workpieces, such as parts used in the aerospace, automotive and mold industries. Due to the large cutting force, it can effectively handle high-strength and wear-resistant materials to meet large-scale machining needs.

Efficient removal of large amounts of material: In the heavy cutting process, large cutting depths and widths are usually used, which makes it very efficient in removing large amounts of excess material. This is very suitable for machining tasks that require rapid removal of large amounts of material in the roughing stage.

Lower tool wear: Although the cutting force is large, the tools for heavy-duty cutting often use high-hardness materials and solid structures, which can effectively resist long-term loads and pressures, so the tool wear is low and can ensure long-term stable operation.

Disadvantages:

High cutting force and heavy machine load: Since heavy-duty cutting requires higher cutting force, the rigidity and power requirements of the machine tool are higher. The heavy load of the machine tool is prone to vibration and thermal deformation, which may affect the processing accuracy.

Slow processing speed: Compared with high-speed machining, the processing speed of heavy-duty cutting is usually slower, especially when fine machining is required. Although a larger cutting depth and feed rate can increase the removal rate of a single cut, the processing efficiency is relatively low.

High energy consumption: Heavy-duty cutting requires higher cutting force and power support, so the corresponding energy consumption is higher. This not only increases production costs, but may also have a greater impact on the environment.

2. High-Speed Machining

Advantages:

High processing efficiency: High-speed machining can significantly improve processing efficiency by quickly removing materials through high speed and high feed rate. For the fine processing of complex parts, it is especially suitable for fields with high precision requirements, such as mold manufacturing and electronic product processing.

Good surface quality: High-speed processing can reduce the heat impact and cutting marks during processing, so a smoother surface quality can be obtained. For some precision parts that require high surface quality, high-speed processing has obvious advantages.

Reduce tool wear: During high-speed processing, the cutting temperature is relatively low, which reduces tool wear. This extends the service life of the tool, thereby reducing production costs.

Lower energy consumption: High-speed processing usually uses a smaller cutting force, so the power consumption of the machine tool is lower, and the energy consumption is relatively less, which is in line with the trend of modern green manufacturing.

Disadvantages:

Limited applicable materials: High-speed processing is usually suitable for soft materials or materials that are relatively easy to cut, such as aluminum alloys, plastics, etc. For materials with higher hardness and toughness, the effect of high-speed processing will be limited.

Higher equipment requirements: High-speed processing requires the machine tool to have a high rigidity, high precision and high-speed drive system, so the equipment requirements are higher. This means that high-speed processing usually requires more advanced and more expensive machine tools.

Limited machining depth and feed rate: High-speed machining usually uses a smaller cutting depth and feed rate, which limits its application in heavy machining. For rough machining of large-sized workpieces, high-speed machining often cannot provide sufficient material removal.

Thermal deformation problem: Although the cutting temperature of high-speed machining is low, due to the concentration of cutting heat during machining, the problem of thermal deformation of the workpiece may still occur. For some parts with extremely high precision requirements, thermal deformation may affect the machining results.

3. Application scenarios of heavy-duty cutting and high-speed machining

Heavy-duty cutting:

Suitable for rough machining of large-sized and heavy workpieces, such as large molds, heavy structural parts, etc.

Suitable for materials with high hardness and difficult to cut, such as high-alloy steel, titanium alloy, etc.

High-speed machining:

Suitable for small-batch, high-precision machining tasks, such as precision molds, aviation parts, and complex curved surface machining.

Suitable for products that require high surface quality and small machining volume, such as electronic product housings, medical devices, etc.

Conclusion

Heavy-duty cutting and high-speed machining each have their own unique advantages and limitations. When choosing a suitable processing mode, companies need to make comprehensive considerations based on factors such as the size, material, precision requirements, and production efficiency of the workpiece. If the main task is to remove a large amount of material and the workpiece is relatively rough, heavy cutting is undoubtedly the best choice; if high precision and surface quality are the focus, and the workpiece material is soft, high-speed processing is more appropriate. By choosing a reasonable processing mode, production efficiency can be maximized and processing quality can be guaranteed.