With the increasing requirements of the manufacturing industry for efficient and high-precision production, heavy-duty moving column CNC machining centers have become one of the important processing equipment. This type of machining center is widely used in aerospace, automotive, mold and other industries, and is capable of high-load and high-precision cutting tasks. However, due to the large cutting force and load it bears, good maintenance and care are required to ensure its long-term stable operation. The following is a maintenance guide for heavy-duty moving column CNC machining centers.

1. Regular inspection and cleaning

1.1 Cleaning the appearance and workbench of the machine tool

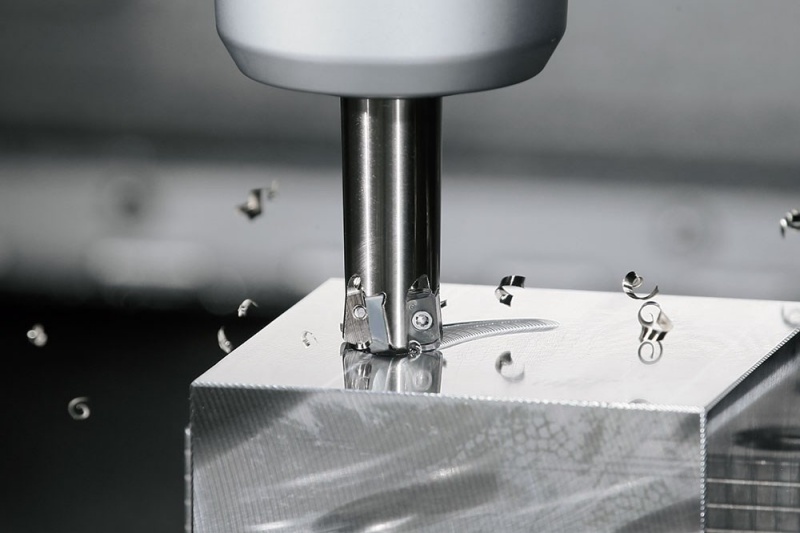

Regularly cleaning the appearance and workbench of the machine tool is an important step to keep the equipment in good condition. During the processing, impurities such as chips, oil, and dust will adhere to the surface of the equipment. These substances not only affect the appearance of the equipment, but may also cause wear of machine tool parts. Therefore, after each processing, especially when heavy cutting is performed, the workbench and equipment surface should be cleaned in time.

1.2 Cleaning the cooling system

During heavy cutting, the circulation system of the coolant is crucial. After long-term use, impurities and dirt in the coolant may cause system blockage and affect the cooling effect. Therefore, the cooling system should be cleaned regularly, and the filter and oil tank should be checked to ensure the smoothness and effectiveness of the coolant.

2. Maintenance of the lubrication system

The lubrication system of the heavy-cutting dynamic column CNC machining center is the key to ensuring the long-term and efficient operation of the machine tool. The system usually includes multiple components such as the spindle, sliding guide rails, gearboxes, etc., and the lubricating oil needs to be checked and replaced regularly.

2.1 Check the oil level and oil quality

Check the oil level of the lubricating oil regularly to ensure that there is enough lubricating oil in the lubrication system to ensure the normal operation of each component. At the same time, the oil quality of the lubricating oil should be checked regularly. If the oil turns black or impurities appear, the oil should be replaced in time.

2.2 Maintenance of lubrication pipelines

The lubrication pipeline system must be checked regularly to prevent problems such as blockage and oil leakage. The joints of the lubrication pipeline need to be checked regularly and tightened to avoid oil leakage due to looseness.

3. Spindle and motor maintenance

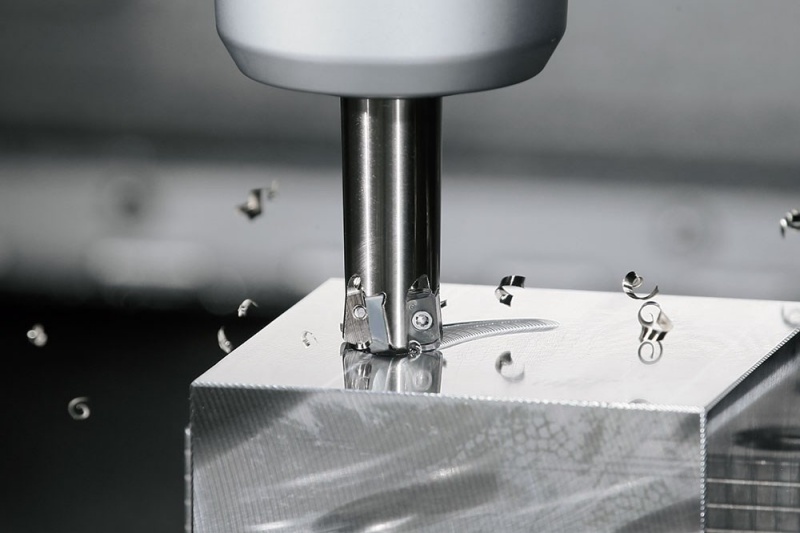

The spindle and motor of the heavy-cutting dynamic column CNC machining center are key driving components, which are subject to huge cutting forces and loads and are prone to wear and overheating. Keeping the spindle and motor in good condition helps improve the processing efficiency and accuracy of the equipment.

3.1 Regularly check the spindle

The spindle should be checked regularly for excessive wear, abnormal temperature and other problems. If the spindle is found to rotate unsmoothly or make abnormal sounds, there may be problems inside the spindle, which should be checked and repaired in time. In addition, the seals of the spindle should be checked regularly to avoid leakage of coolant or cutting fluid, which will affect the performance of the spindle.

3.2 Motor heat dissipation and maintenance

The heat dissipation effect of the motor directly affects its service life. The heat dissipation channel of the motor should be cleaned regularly to prevent dust and oil from blocking the heat dissipation holes. If necessary, use special tools to clean it to ensure that the motor does not overheat during operation.

4. Accuracy inspection and adjustment

Accuracy is one of the most important performance indicators of CNC machining centers. In order to ensure machining accuracy, heavy-cutting moving column CNC machining centers need to be regularly inspected for accuracy and adjusted as needed.

4.1 Position accuracy inspection

Regularly check the position accuracy of the machine tool, such as the zero return accuracy of the X, Y, and Z axes, the position feedback accuracy, etc. Precision deviation may be caused by the accumulation of errors in the mechanical structure, servo system or electrical system. If the precision deviation is found to be beyond the allowable range, calibration should be performed.

4.2 Tool deviation and calibration

Due to long-term use, the wear of tools and tools may lead to a decrease in machining accuracy. Check the tool regularly for deviations and calibrate or replace them. In addition, the tool sensor should be calibrated regularly to ensure the accuracy of the tool position.

5. Control system maintenance

The CNC system is the "brain" of the heavy-cutting moving column CNC machining center, responsible for processing the machining program and controlling mechanical movement. Regularly checking the operating status of the control system to ensure the normal operation of the system software and hardware is an important part of equipment maintenance.

5.1 System software update

The control software of the CNC system should be updated regularly to use new functions and improve system stability. Be sure to check and upgrade the system software regularly according to the manufacturer's recommendations.

5.2 Check the electrical system

The electrical system of the heavy-cutting moving column CNC machining center includes sensors, encoders, power supplies and other parts. Regularly check the electrical system for faults or abnormalities to ensure stable transmission and correct feedback of electrical signals.